Experimental Design

ME 4880 // Completed December 2020

SUMMARY

Experimental Design is a class where advanced instrumentation systems are used to conduct experiments. The data gathered during these experiments is then used to develop formal lab reports. Statistical significance and error analysis are underscored as experimental design principles.

The final project for this class is a study of the effect of different 3D printing conditions on the mechanical properties of a standard ASTM D638 sample loaded in tension. To develop a comprehensive analysis four different orientations with three different layer heights are studied. The results from this analysis are then used to recommend a print condition for a phalangeal joint in a prosthetic hand.

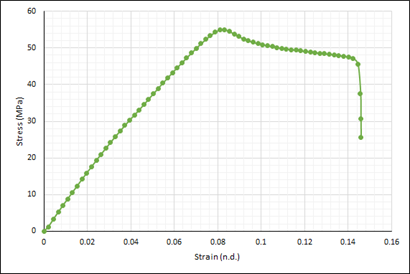

A tensile test is used to understand the material response and is replicated a total of ten times for each unique print height and layer orientation. A stress-strain curve developed from a tensile test is shown below.

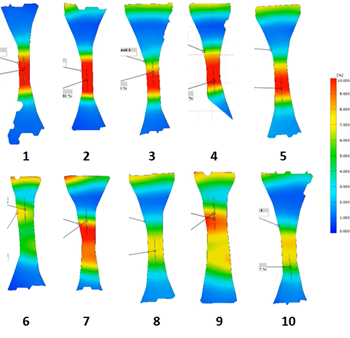

The data gathered by the tensile test is then verified by the use of digital image correlation (DIC). The following image shows the localized yielding for ten samples at a particular print height and layer orientation.

The report in its entirety can be found below as submitted in December of 2020.